|

|

|

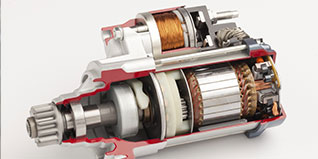

Electrical Equipment |

Spare Parts |

|

|

Fabric dust collectors are commonly known as bag filters and Bag houses are the most efficient and cost effective dust collector models. Dust enters the fabric filter compartment. Larger particles drop out while smaller dust particles collect on filter Bags. When the dust layer thickness reaches a level where flow through the system is restricted (called pressure drop or delta P), the bag cleaning process is initiated. Cleaning can be done while the compartment is still online (filtering) or in isolation (offline). Once cleaned, the compartment is placed back in service and the filtering process starts over. There are three prominent types of cleaning process in bag filters and bag houses: Reverse Air (Gas Cleaning), Pulse Air (Compressed Air Cleaning) and Shaker (Mechanical Cleaning). Bags are made of different material such as woven or felted cotton, synthetic, or glass-fiber. We do support Control Units for all type of equipment, including; ESP, bag house and bag filter. |

Vira Vision, using the benefit of fully equipped workshops and expert assistance; supply the widest selections of commonly needed components in the industry at any quantities with competitive price and best quality. They are interchangeable with the original parts. Our supplies include but not limits to electro motors, cage, bag, venturi, collecting plate, discharge electrode, rapping hammer or any special related part according to your requirement. (If you have any other inquiry, kindly please let us know and contact us.) |